Application and function

Application and function

It is widely used in corn, wheat, rice, sorghum, job’s tears, vegetable seeds, beans and other commercial grain and economic crops.

Remove light skin, lint and dust from materials;

Remove large and small impurities in materials;

Remove the impurities such as empty shells, moldy, dried grains and immature grains in the materials.

Principle and applicability

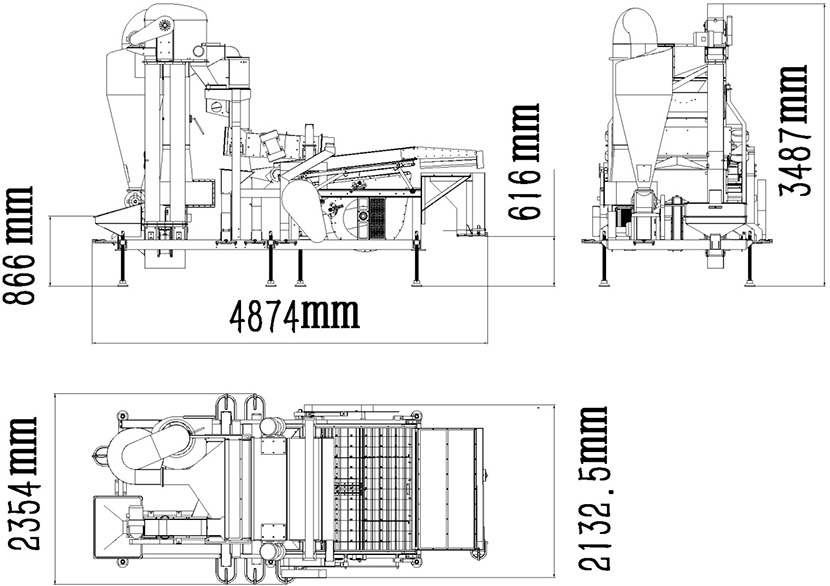

The Air Screen Cleaner with Gravity Table mainly includes elevator, bulk grain box, air screen, screen box, gravity table, dust removal system and other structures.

Processing : after feeding, the material is lifted to the bulk grain tank by the elevator, and enters the air screen evenly through the bulk grain function. The dust and light impurities with small proportion in the material are separated by the dust removal system. The material enters the screen box, and the big and small impurities are removed through the hole screen. After screening, the material enters the gravity table, and the heavy light impurities such as mildew and empty shell are removed through the interaction of wind force and vibration. The material enters the back half screen for secondary classification screening,to improve the filtering accuracy.

This equipment is mainly used for the pre cleaning, removing dust, whisker, empty shell, orange stem, mildew particles and other impurities. It is characterized by large output, energy conservation and environmental protection, and high cost performance.

Technical advantages

1, With mature air separation device, collect dust and light impurities effectively, clean and environmental protection;

2,Multi-function: air selection, screening and specific gravity, reducing labor, site saving, energy saving and consumption reducing;

3,Double vibration motor, high frequency, low amplitude, self vibration balance, etc., more stable.

4,Gravity table vibration and eccentric drive vibration, independent vibration source, high stability.

5,Ultra-low speed non broken elevator to minimize broken loss.

6, The first step is to remove impurity by the gravity table, which can effectively improve the purity of the materials on the Gravity separator, reduce the screening pressure on the gravity table, and improve the output and purity.