Application and function

It is widely used in the processing of various crops,grains and food, such as grains, beans, fried goods, traditional Chinese medicine, seeds, dried fruits, nuts, corn, wheat, rice, etc.

Remove the husk, whisker, stem, leaf, dust and other light impurities in the material;

Remove large and small impurities in materials;

The materials are sorted into large, medium and small particles.

Principle and applicability

5XFS series Air Screen Cleaner can separate the dust and light impurities with small proportion in the materials through air separation; remove the large and small impurities with large size difference in the materials through precision punching screen, and sort the materials into large, medium and small particles according to the size of the materials; separate the air and light impurities by cyclone. With a non broken elevator to minimize material crushing.

It is suitable for the initial processing of products, providing materials with less impurities for subsequent cleaning equipment, and improving the separation efficiency and accuracy.

Technical advantages

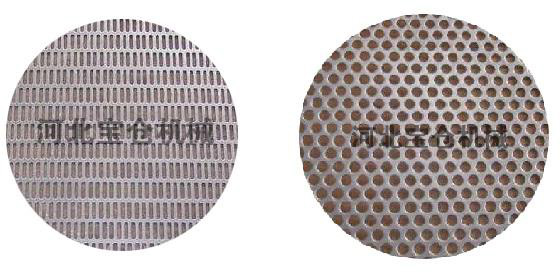

1, Precision punching mesh, high grading accuracy.circular holes for width resolution and long holes for thickness resolution.

2.Installed with 1-4 layers, 5 levels at most, adjusted flexibly.

3.Double vibration motor, high frequency, low amplitude, self vibration balance, etc., more stable.

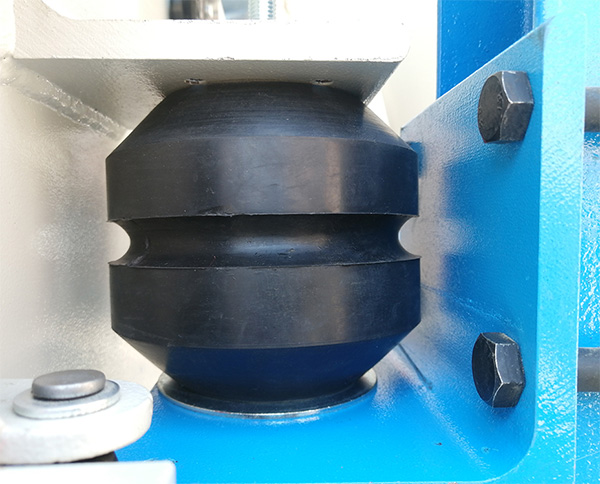

4.High-quality rubber damping module,long service life.

5.High elastic rubber ball, automatic screen cleaning, and avoid screen blocking.

6,With cyclone and rotary discharge valve, environmental protection.

7, Non broken elevator to minimize material broken.

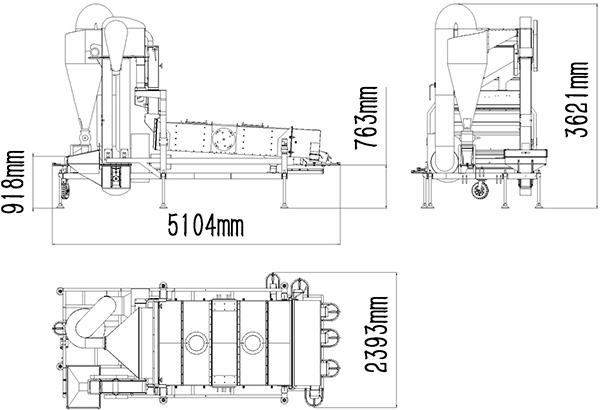

Products size:

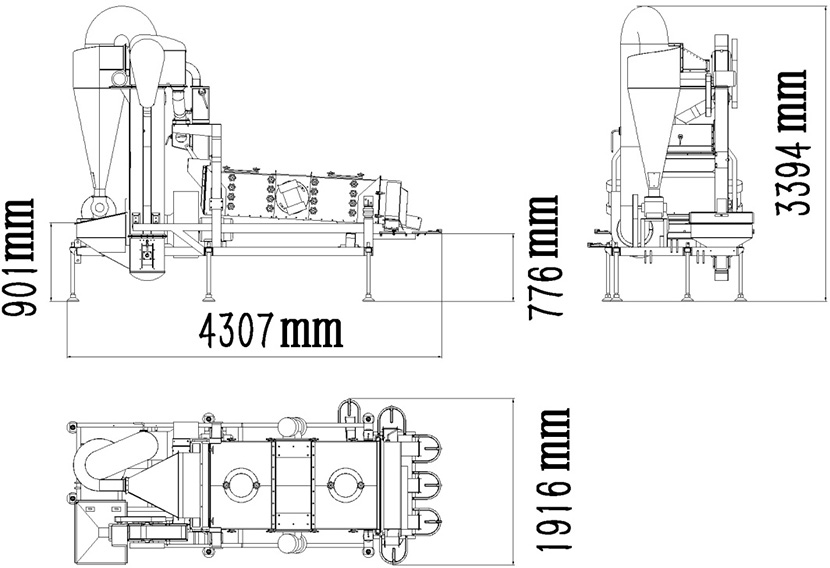

1.5XFS-5 Air Screen Cleaner Size

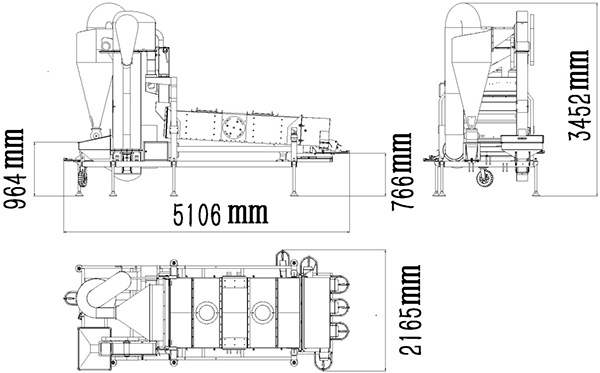

2.5XFS-7.5Air Screen Cleaner Size

3.5XFS-10Air Screen Cleaner Size