Applications and functions

It is often used for polishing various kinds of legumes, grains, grains, other seeds and other crops and food.

Remove the dust and adherents on the surface of the material particles, and the surface of the particles shall be bright and beautiful.

Principle and Applicability

Polishing machine is to use rotary cotton cloth to stir materials, and use cotton cloth to wipe off the dust and attachments on the surface of materials, so as to make the surface of particles look bright.

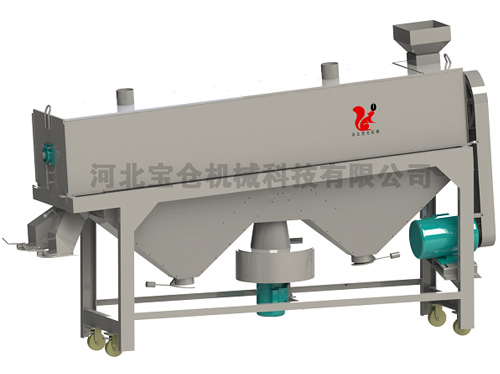

The internal structure of the polishing machine includes the central shaft, the outer cylinder, the frame, etc. a large number of cotton cloth is fixed on the surface of the central shaft. The cotton cloth is specific structure and the specific track installation. The outer cylinder is the cylinder wall of the polishing work. The woven mesh with holes is used to discharge the dust generated by the polishing in time.

The equipment has feeding inlet, finished product outlet and dust outlet. When in use, it should be connected with the elevator to feed materials.

Polishing machine will produce a certain amount of broken, which is not suitable for fragile materials.

Technical advantages

1, Metal spindle

The central axis adopts the metal spindle, and the cotton cloth is fixed on the surface of the spindle by bolts, to increase the service life of the spindle and facilitate the replacement of the cotton cloth.

2, Pure cotton

Pure cotton polishing cloth,good adsorption and improves the polishing effect.

3, 304 stainless steel mesh

304 stainless steel woven net, excellent wear resistance,long service life

4, Fan dust removal

The whole polishing chamber is in the state of suction negative pressure, and the dust generated can be discharged in time to avoid the dust concentration which affects the polishing effect.

Optional models

5XPG-5

5XPG-5G

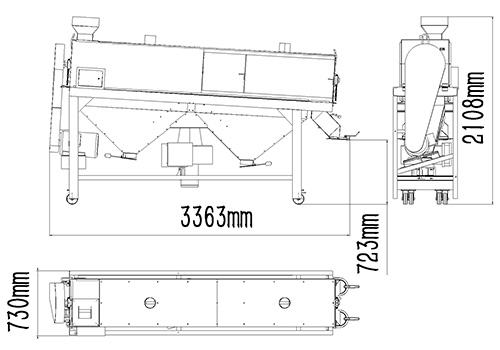

Product selection size