Application and function:

It is widely used in grain storage, grain processing, oil processing, grain food and grain feed industry.

Lift the material from the feeding hopper to the inlet of the processing equipment to provide stable feeding for the subsequent equipment.

Principle and applicability:

The traction belt is around the head wheel and the bottom wheel, and the buckets are fixed on the traction belt according to a certain distance. The shell seals the buckets and the traction belt. The materials enter the moving buckets from the machine base, lift along the machine barrel, and the materials are thrown out of the hopper at the machine head and discharged out of the machine through the discharge pipe.

The equipment is suitable for vertical conveying of materials, with low broken rate and wide range of materials, but it still has certain broken when it is used for other more easily damaged materials such as activated carbon and peanut kernel.

Technical advantages

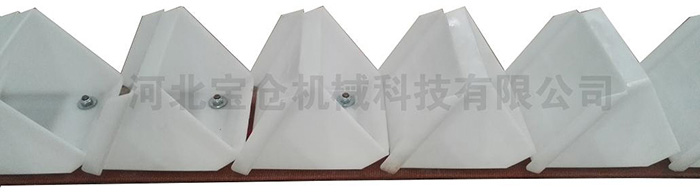

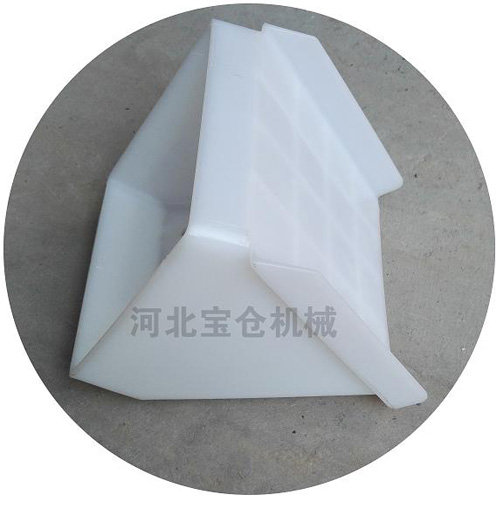

1. The elevator adopts DM type low damage buckets, with unique unloading mode. The material in the latter buckets flows out along the chute at the bottom of the previous buckets. Slow gravity type unloading, smooth unloading process, so as to reduce the broken rate.

2. The buckets are made of high-density polyethylene, which has excellent wear resistance, impact strength and long service life.

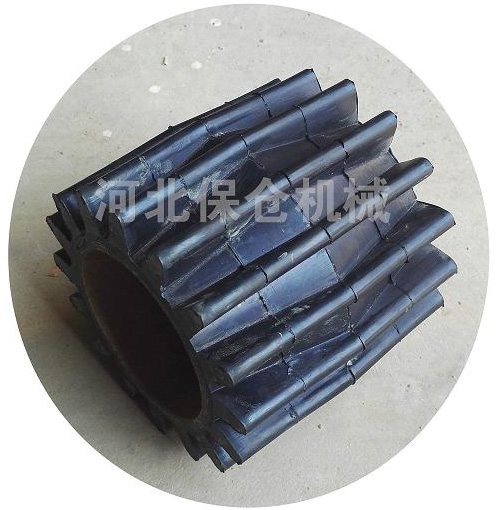

3. The bottom wheel of the elevator adopts the flower shaped rubber wheel to avoid rolling materials.

4. The anti winding design is adopted for the rotating shaft of the elevator to avoid the twine and other things mixed in the materials from winding on the rotating shaft.

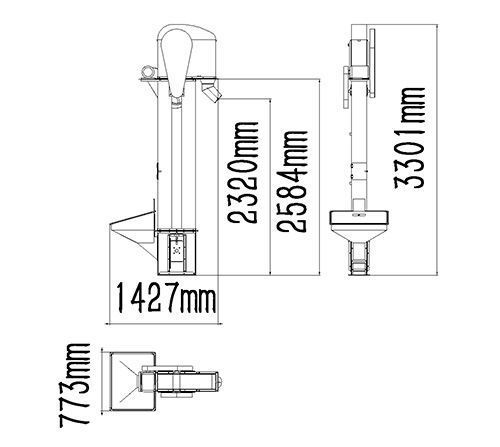

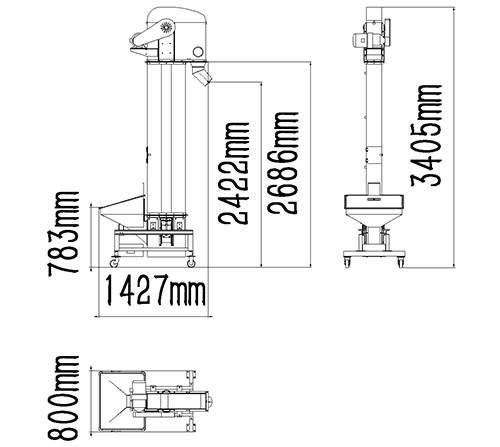

Products size